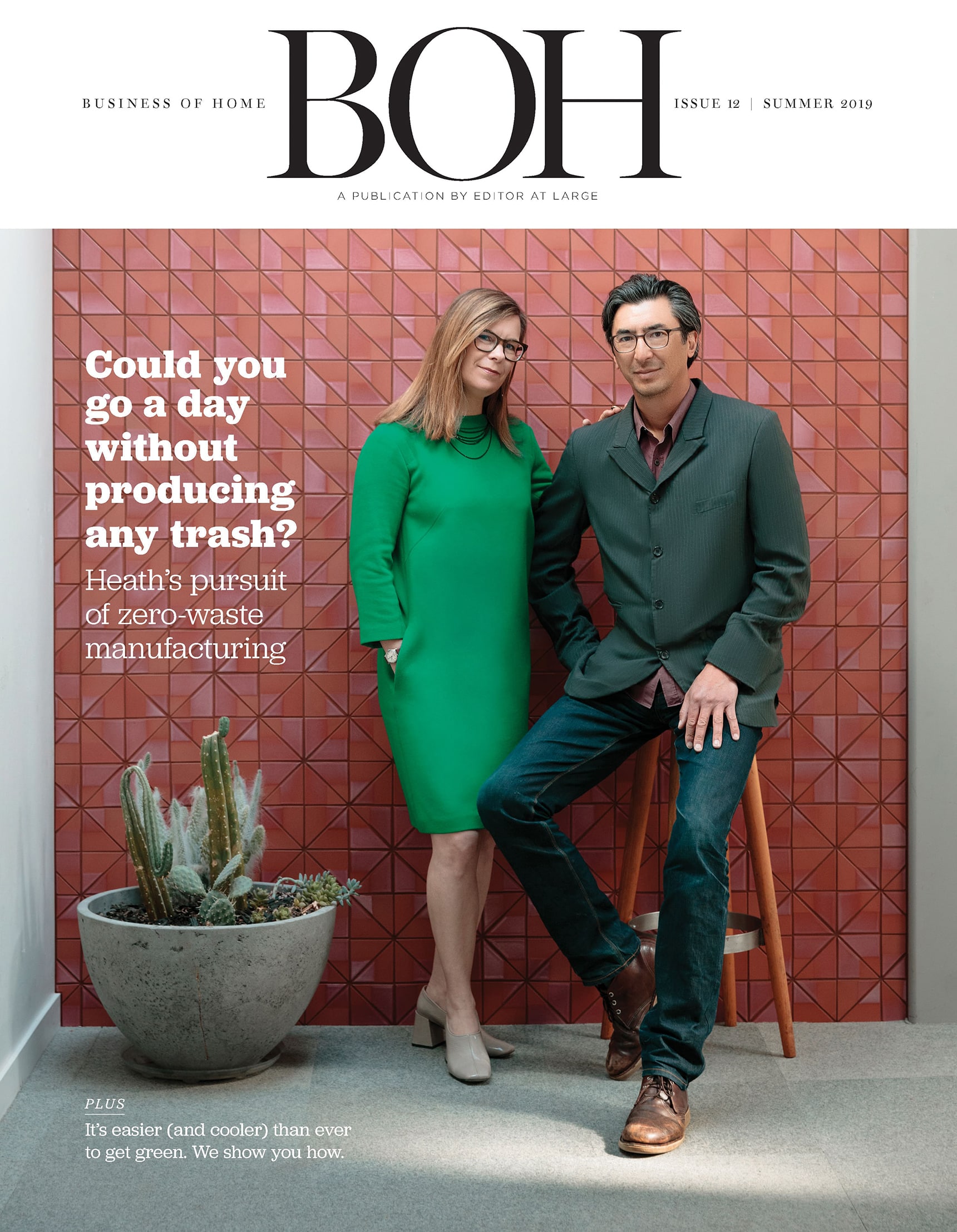

For more than a decade, Susan Inglis has steadily and tirelessly beat the drum for green practices in the home furnishings industry.

The graphics weren’t fancy: Helvetica font, low-resolution logos, and two illustrations of Earth, one of which appeared in flames alongside frightening climate-change statistics. It was the first day of spring, and Susan Inglis, executive director of the Sustainable Furnishings Council, was hosting a webinar for the Interior Design Society. Her lilting North Carolina cadence, homespun good nature and calm demeanor (despite some very real sky-is-falling exigencies) made the learning process not only fascinating but unexpectedly pleasant. Even the name of the session—“What Is Sustainable Furniture Anyway?”—sounded approachable. In this era of Goop-ified science, devastating natural disasters and plastic-straw bans, you could almost be forgiven for not grasping—or wanting to face—the overwhelming threat to our environment. (The planet is on fire and we’ve been busy thinking about the lead time on that sofa.) But Inglis is trying to make you care.

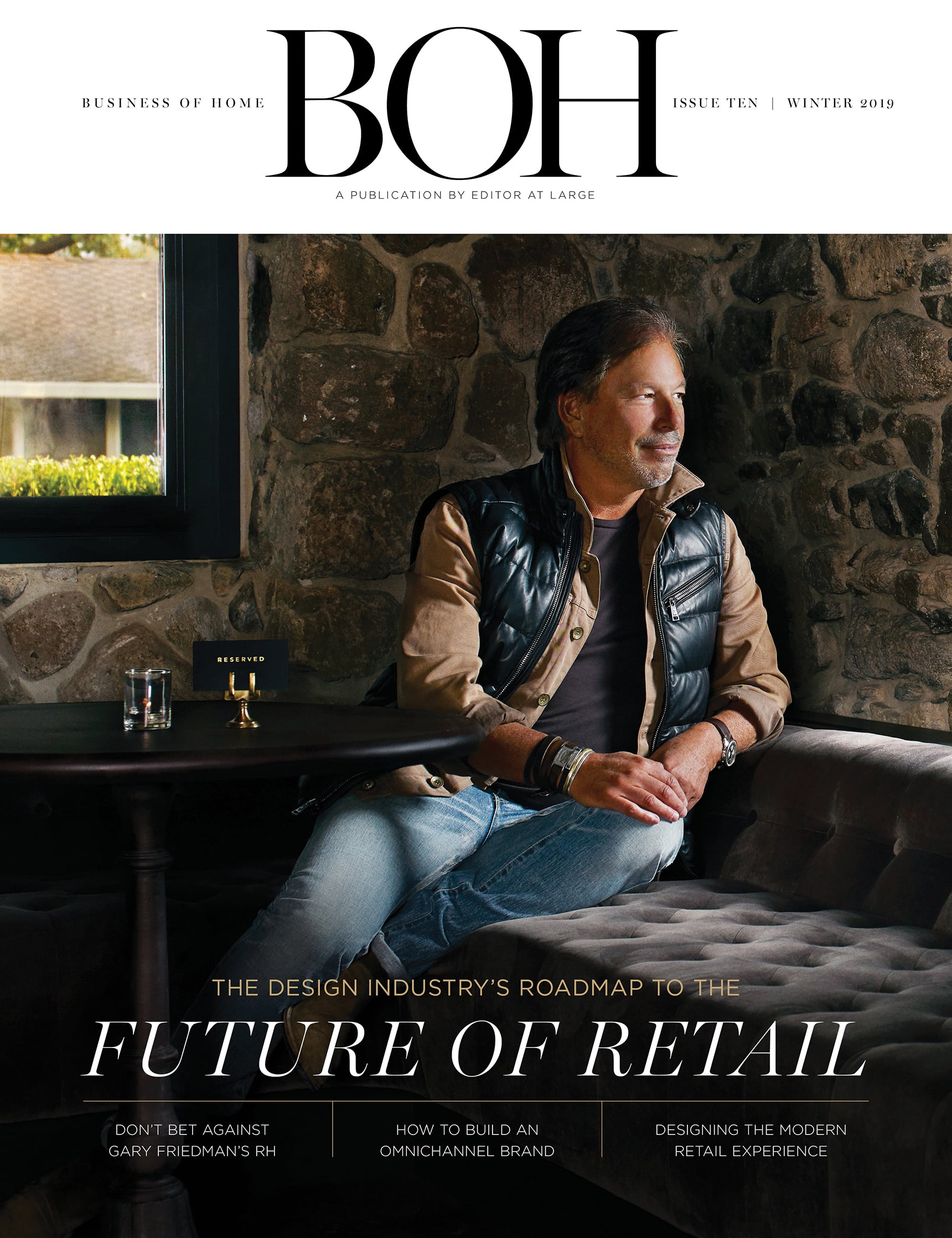

Though the design industry is charitable in countless meaningful ways, the ironies emerge everywhere. Sustainability was the prevailing topic during the latest edition of Milan Design Week, with several high-profile exhibitions sounding the alarm. But the act of constructing a temporary installation inherently requires putting more disposable materials into the world and exerting more energy—all on something that is quickly taken down. And even with a spot-on message about the looming environmental crisis, there were parties featuring plastic cups and cocktail napkins.

The industry tends to treat sustainability like a diet: A little junk isn’t going to kill us, we tell ourselves. If you’re buying primarily vintage and antique pieces—the design industry’s ultimate example of reuse—it can be easy to tell yourself that ordering that one stool online and having it sent next-day air isn’t the worst thing in the world. Or maybe it takes the right soul to remind us that real reform only happens through a million tiny steps—and a million more tiny but important choices.

BOH subscribers and BOH Insiders.