Bay Area interior designer Leah O’Connell had long nurtured a dream of starting her own textile line. Here, she tells us how a trip to Ireland—and some pandemic downtime—finally got her started.

I know a lot of designers start a room by picking rugs first, but for me, it’s textiles—they’re just what makes me happy and the reason I love interior design. I wanted to start my own fabric line for the longest time, but it was one of those things you put off and put off. I had gotten used to thinking I was never going to follow through with it.

Right before the pandemic, I was lucky enough to go on a trip to Ireland, where I stayed in some incredible places, like Ballyfin, a hotel crafted out of a restored country estate. There’s something special about those houses in the British isles. As grand as they are, they’re so casual, unpretentious and intimate. You walk in and feel like they’re giving you a hug. I was so inspired, and I came back from that trip thinking that I wanted to try and create that feeling over here.

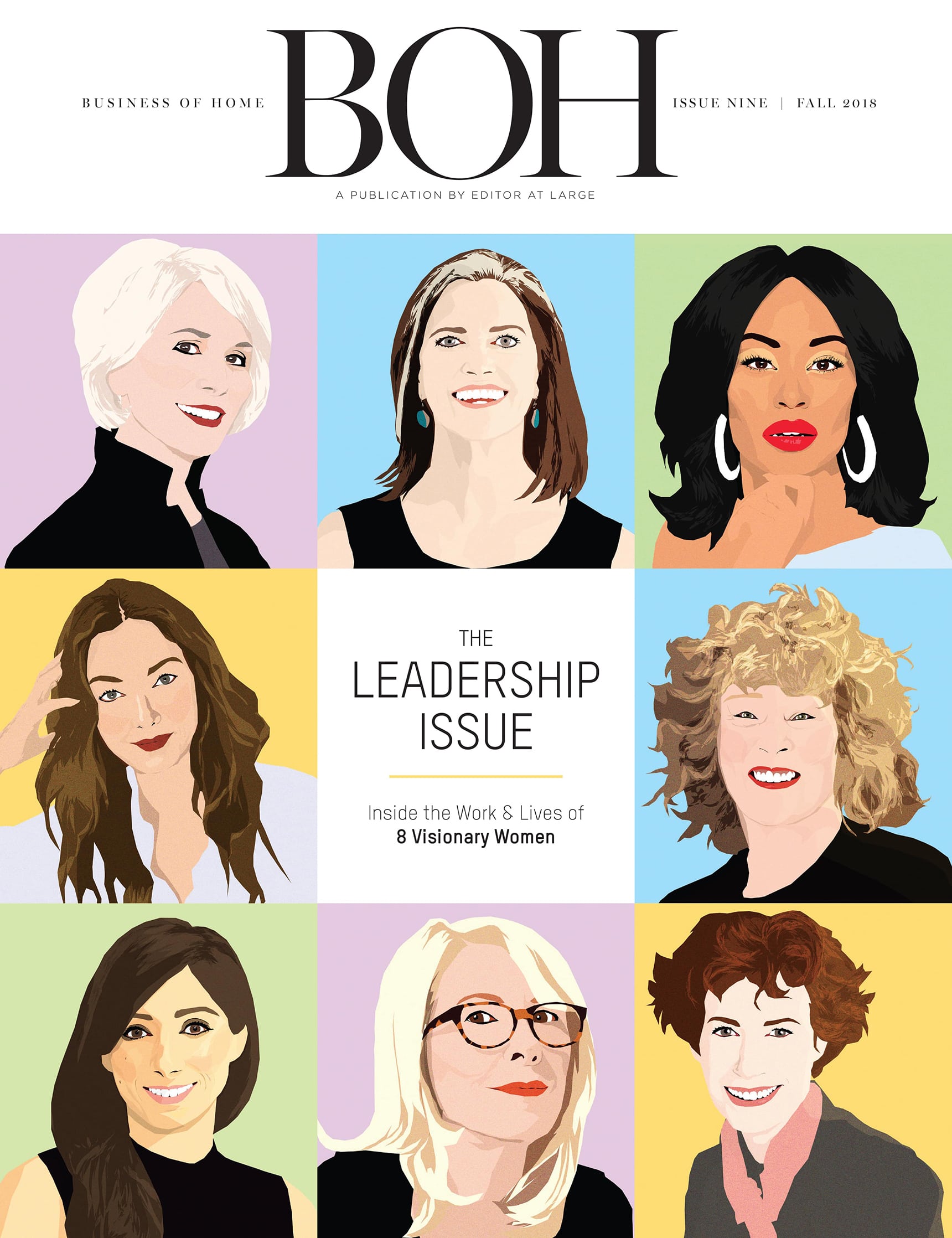

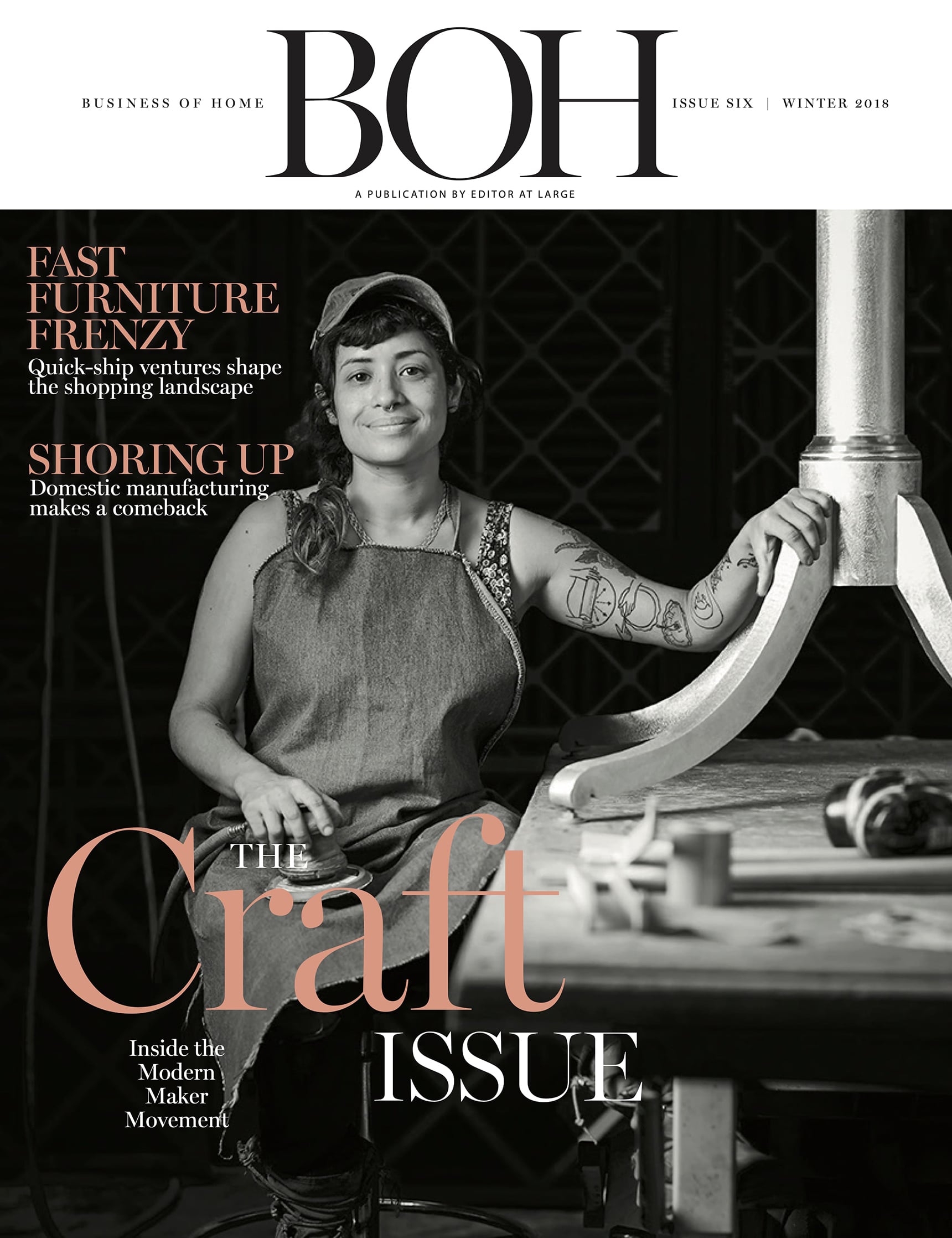

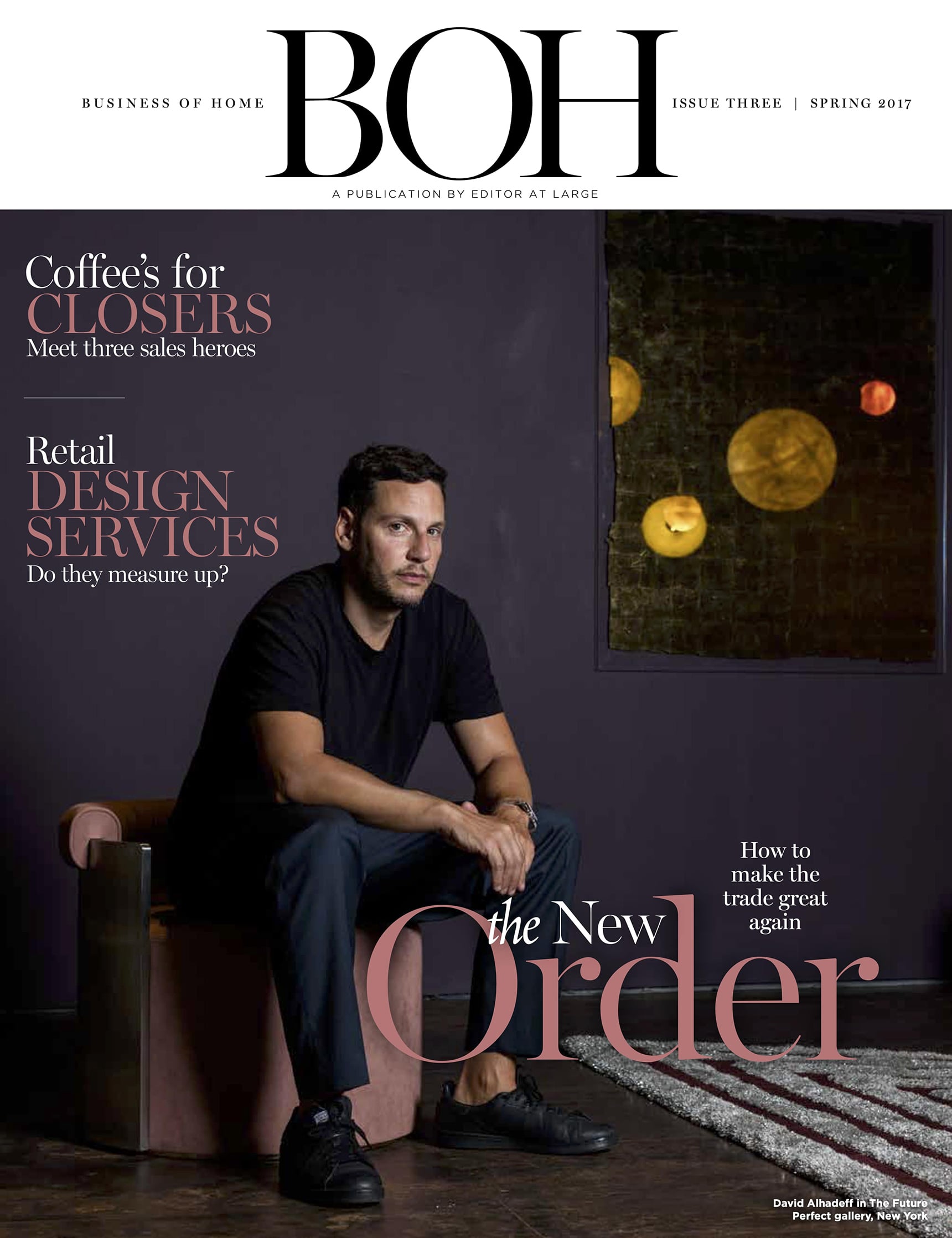

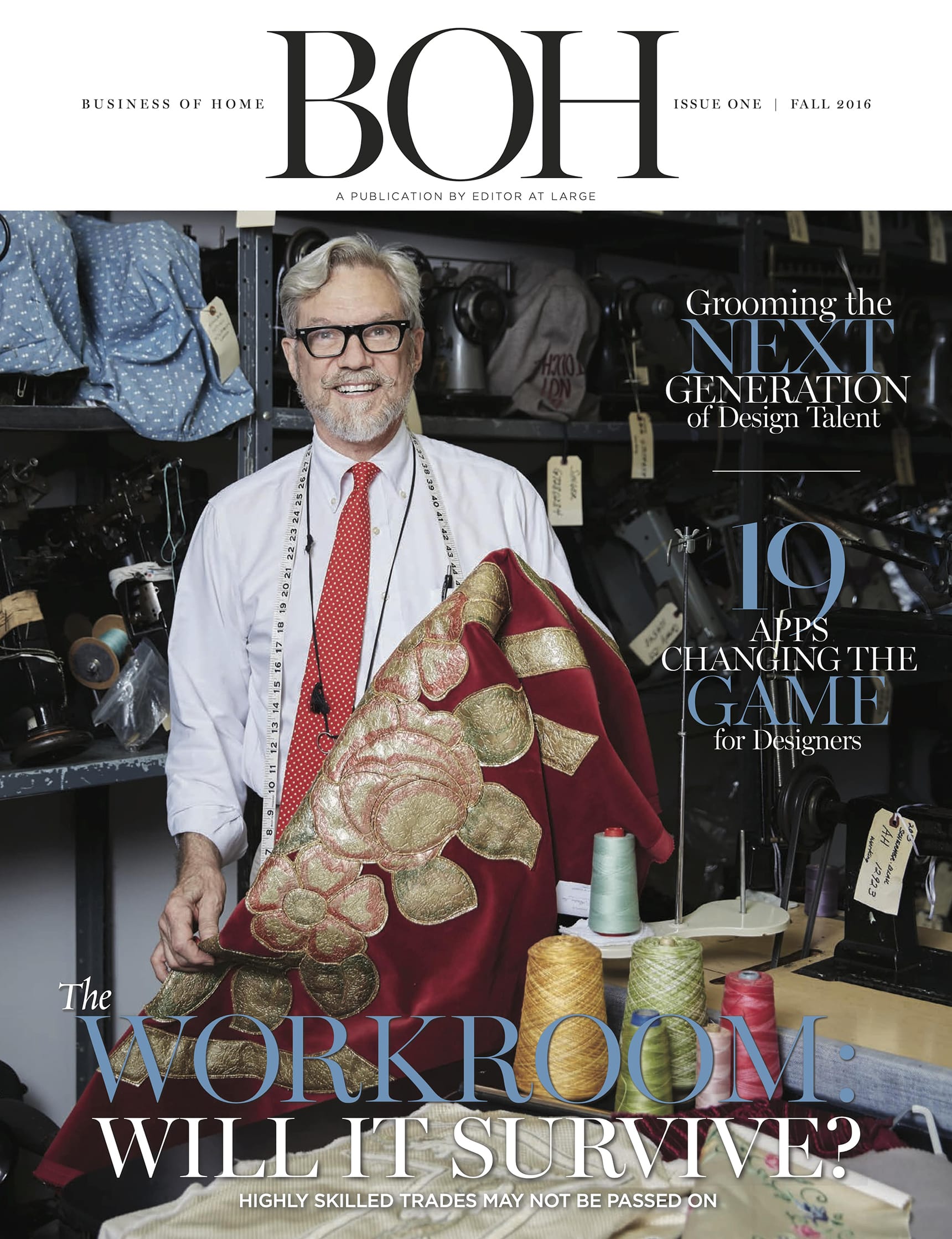

BOH subscribers and BOH Insiders.