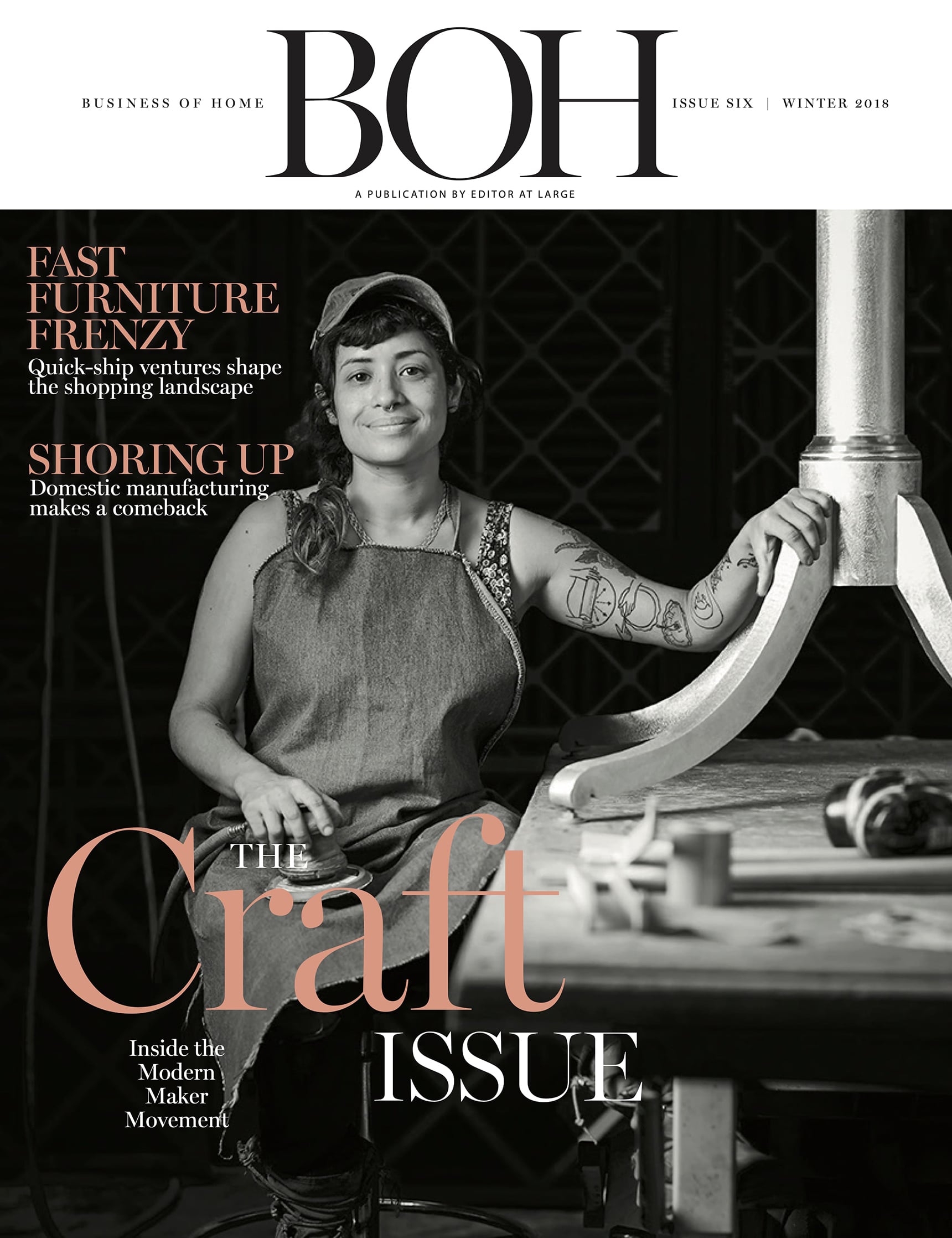

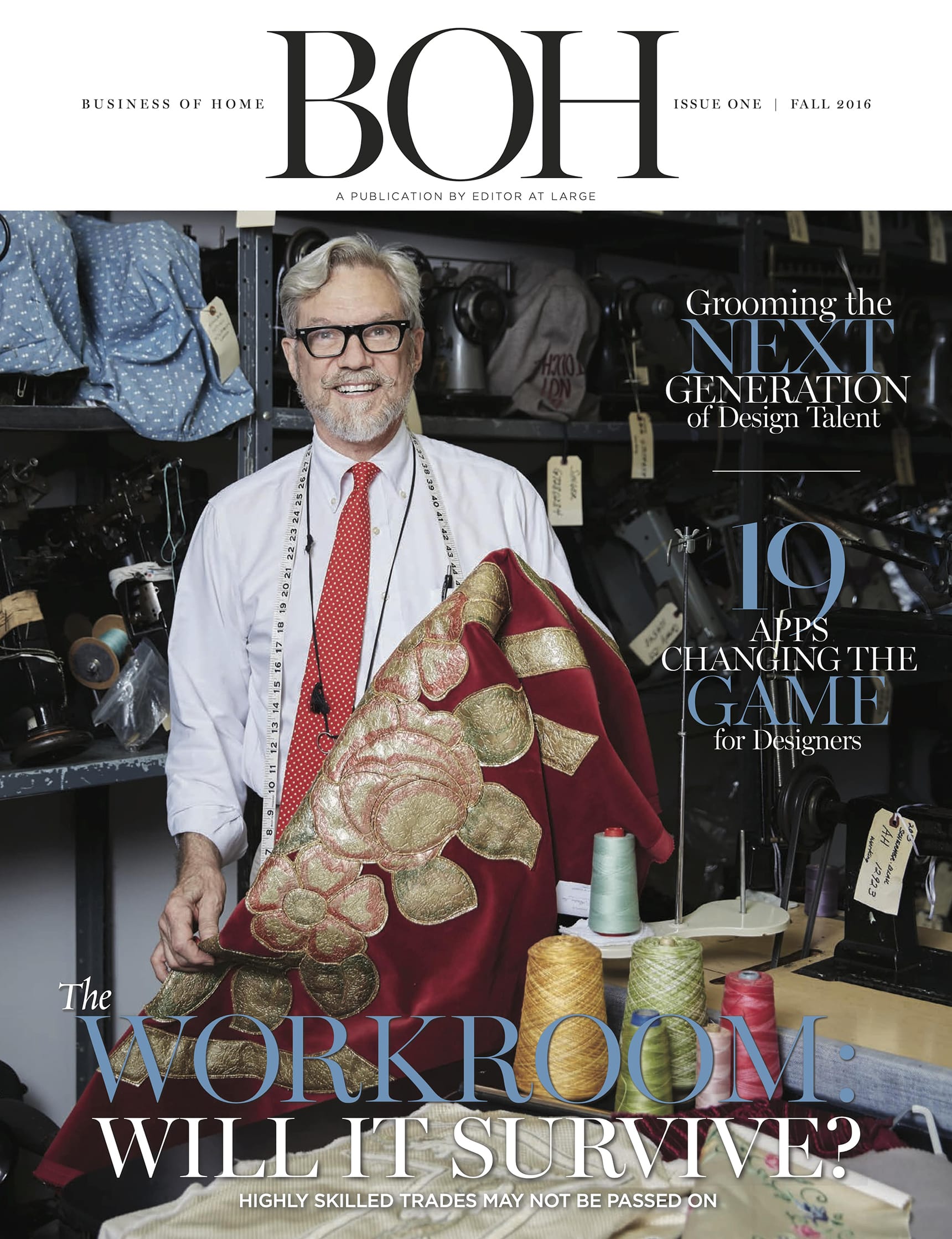

A view inside the made-to-measure world.

This is not our most patient hour. Technology has coddled us. With UberX, track-shipping screens and the indulgent magic of Amazon Prime, a wait longer than five days feels like an eternity.

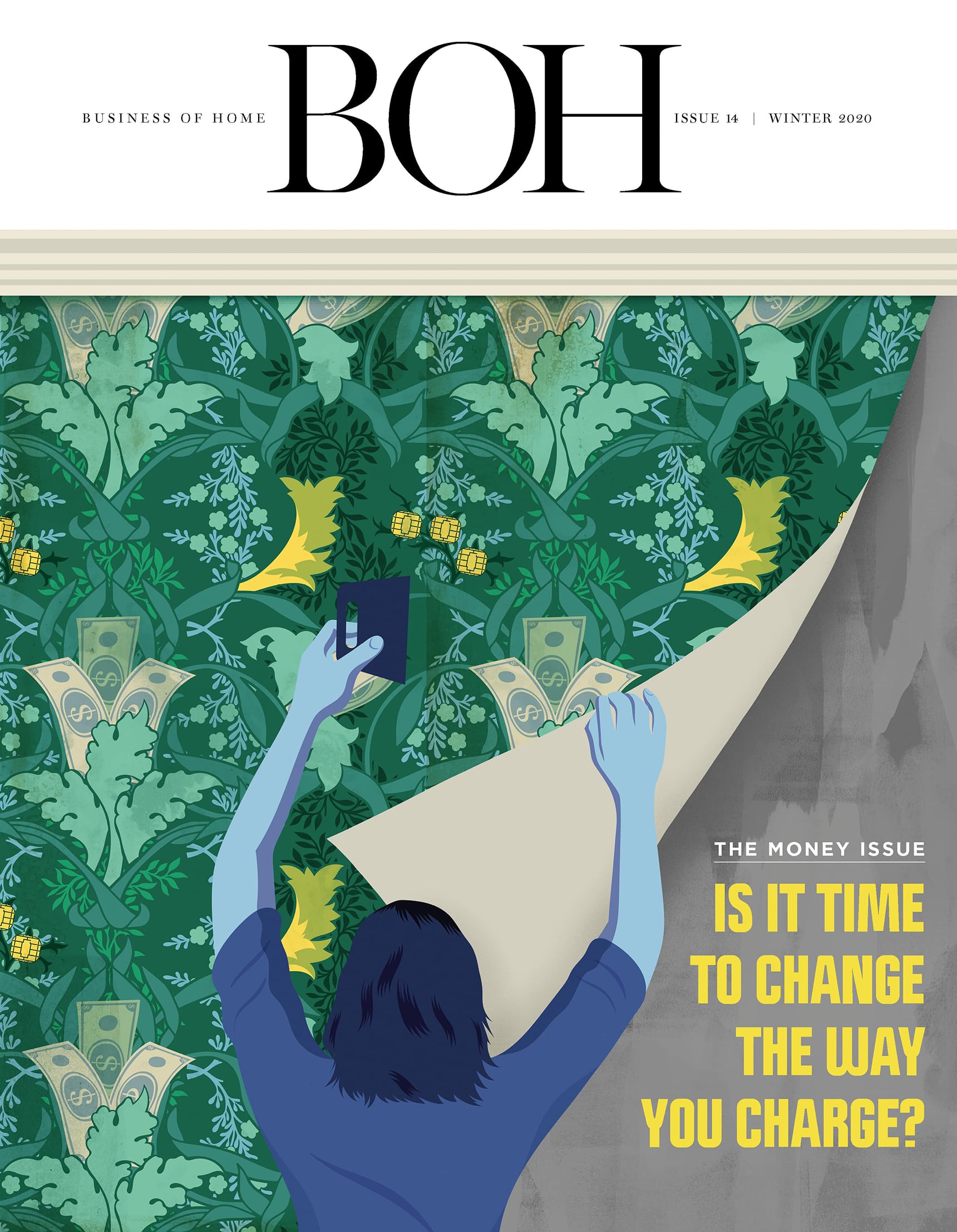

The digital warp is undeniably excellent for interior designers. Yet as we march toward faster-better-stronger, something naturally recedes, sliding further into the Old Way of doing things and treading against market shifts and changing preferences. Within the high-end realm of residential interior design, no other group highlights this story more poignantly than the design workroom. The very essence of these makers—the slow hand of craftsmanship and bespoke artistry—is what makes them both vital and vulnerable. How have their businesses changed? Are they at risk of closing? Is retail the only kryptonite to these specialized heroes? We pull back the pinch-pleated curtain of this rarified world to find out.

BOH subscribers and BOH Insiders.