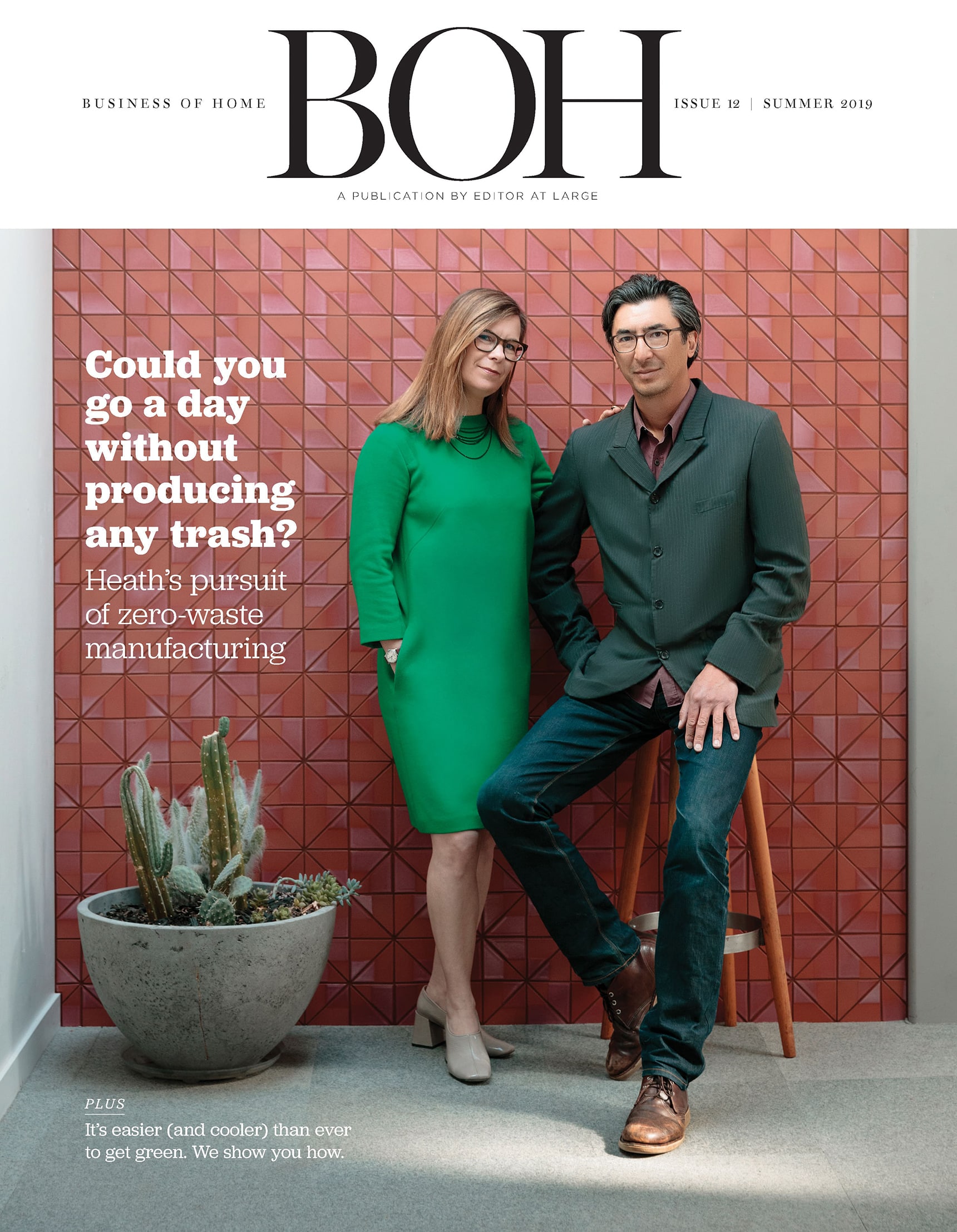

Three years ago, Heath Ceramics embarked on a radical company-wide journey to eradicate waste. BOH caught up with the California-based brand to find out how, why—and how much it (didn’t) cost.

Here’s what they don’t tell you about converting your business to produce zero waste: You can’t really do it, not all the way. There’s always something that slips through the cracks, some tiny scrap of trash scuttling out the door. No company, even one that markets itself aggressively as “zero waste,” is truly zero waste. Some joke wryly that there’s really only one surefire way to get all the way there—shut the factory down.

For those who wish to attempt going zero waste and stay in business, the journey is painstaking and long. So why would a company undergo a difficult process working toward a goal it can never really reach?

Robin Petravic, the co-owner of Heath Ceramics with his wife, Catherine Bailey, has a flat, serious affect and a bone-dry wit. (Once, he told me about an interview with the founder of Clif Bar, Gary Erickson, who said he’d rather poke needles in his eyes than take his company public: “I totally get that,” Petravic added, after a pause.) He and Bailey bought Heath in 2003 from a trust set up to represent the company’s original founders, Edith and Brian Heath. The Sausalito, California–based ceramics company had a storied legacy—since 1948 it had represented a kind of American craft ideal of simple design wedded to high-quality workmanship. At its peak, Heath was producing about 100,000 pieces of dinnerware a year. But by the nineties the company had fallen on hard times and was down to only 24 employees, producing about 40,000 pieces annually. Under Petravic and Bailey’s leadership, Heath has rebounded spectacularly; the company now employs more than 200 and boasts annual revenues of more than $30 million.

BOH subscribers and BOH Insiders.